Your Vessels, Our Expertise

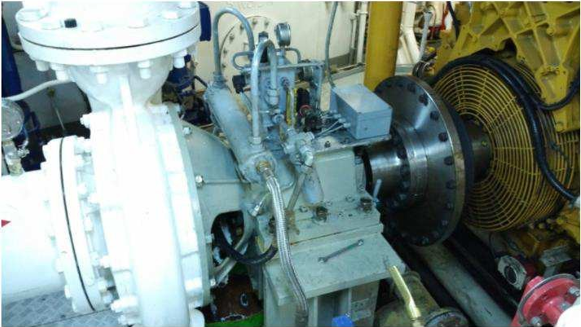

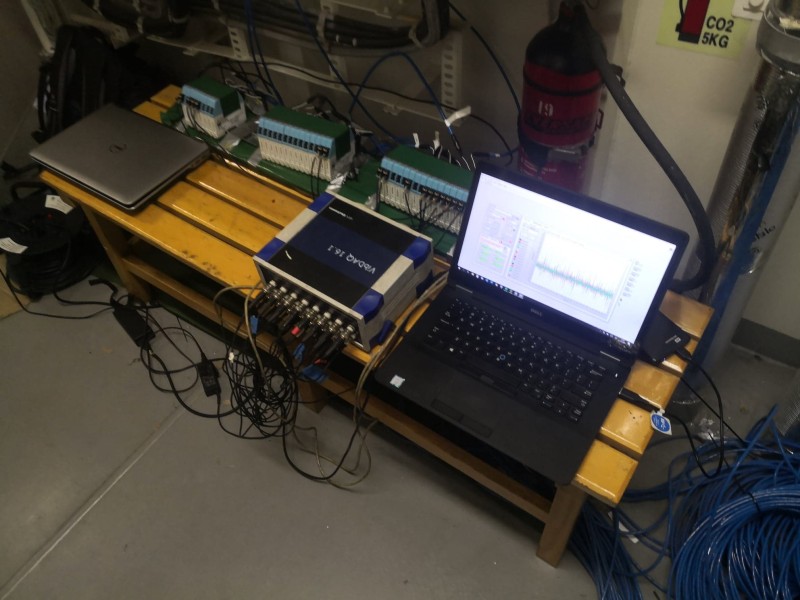

For more than two decades, Info Marine has stood as a reliable provider of expert analysis for marine machinery and hull structures. Throughout our journey, we’ve meticulously prepared thousands of reports and amassed extensive big data on various machinery and vessels. Our committed team excels in diverse measurement techniques, enabling us to accurately evaluate the conditions of machinery and structures and identify the root causes of issues. We deliver a comprehensive solutions, seamlessly progressing from thorough assessments and precise measurements to in-depth analysis.

AI, and Technical Diagnostic Excellence for Smarter Ship Solutions!

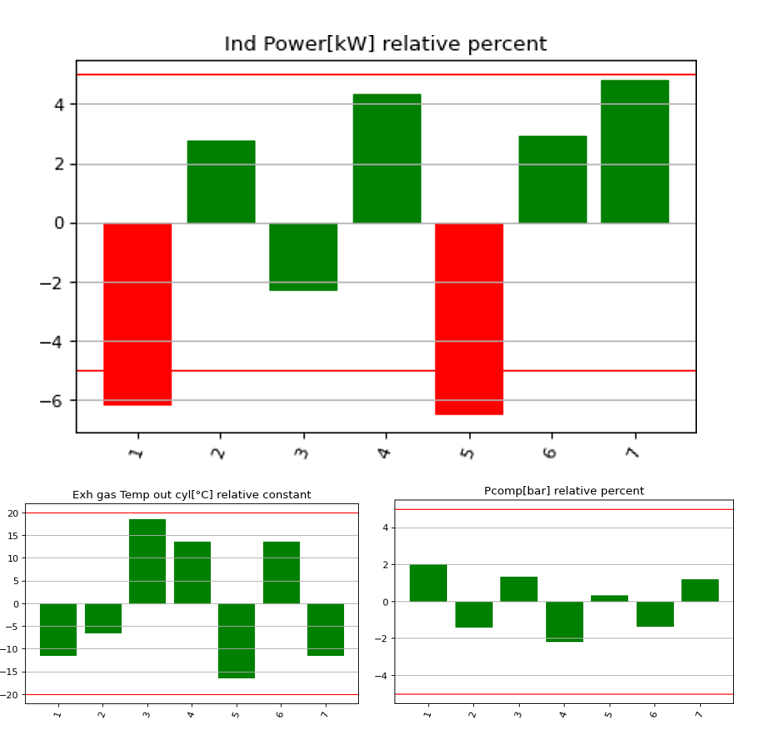

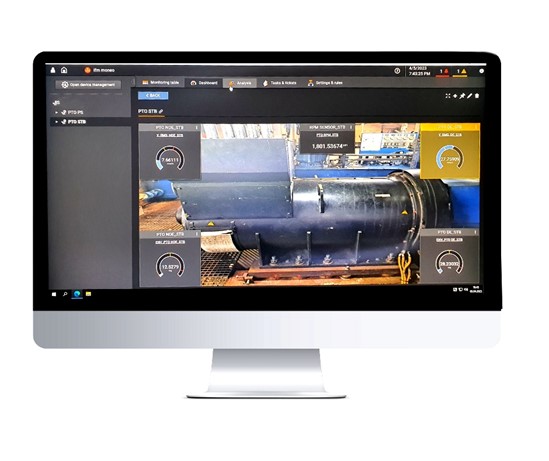

Empowering ship management to proactively avoid critical failures and minimize repair costs is at the core of our mission at Info Marine. The culmination of our efforts results in a user-friendly and transparent technical diagnostic report, accompanied by expert advice and recommendations.

Our approach is grounded in the collective knowledge and expertise of our specialists, augmented by the integration of modern technologies such as AI. By choosing Info Marine, you’re investing in a strategic partner committed to elevating operational efficiency and preventing unforeseen technical challenges in the maritime industry.

Preserving Oceans with Precision: Where Diagnostics Meet Ecology

Info Marine services redefine marine maintenance, minimizing the frequency and scale of necessary interventions. This directly translates to fewer spare parts usage, curbing the environmental impact associated with their production and recycling. By extending running hours between overhauls, our approach not only enhances machinery performance but significantly reduces overall energy waste. Engines, motors, and generators operate more efficiently, resulting in lower power and fuel consumption. While complete elimination of pollution might be challenging, our solutions actively contribute to a greener maritime environment. Through meticulous machinery care, we not only prolong their lifespan but also champion the protection of our precious ecosystems.

Clients’ Problem-Solving

- All

- Case

- Machinery

- Other

- Structure